How it Works

- A partnership from project Start to Finish

- Delta receives ISOs at the same time as you

- Delta keeps a running catalog of all ISOs received

- Catalog contains all needed pipe supports, quantities and spool locations

- Delta names all supports per your specifications and provides PART IDs for your parts library

- Delta does all MTO including CAD drawings and BOMs

- Delta provides all needed info to your Procurement group within agreed upon pricing structure

- ERP system interface can be developed for seamless integration with Delta

- With the go-ahead from procurement (PO#), Delta begins fabrication ahead of schedule

- Delta provides REAL-TIME Production Status Reports throughout the manufacturing process

- Delta tracks all welding qualifications to approved welding procedures on every job, every time

- Delta provides 100% traceability of all materials including filler metals

- Delta provides bar-coded/QR coded supports identified with Detail #, ISO, spool, etc…

- All support info can be provided in advance of shipping for easy receipt and tracking

- Delta assumes all responsibility for ensuring all supports needed for project are correct and on-time

- Delta provides GPS trackable shipping containers for jobs requiring longer lay-downs

- Delta’s Interactive Customer Portal makes project tracking, documentation, information exchange in general… EASY & SECURE!

Have a project? Ready to try a better way?

Contact DeltaTSS Synergies

- On-time deliveries

- Reduced project delays

- Efficiency in engineering parts we know

- Less RFI Holds

- Pre-established smart pricing

- Improved project budgeting

- Minimized expediting fees

- Better transparency for resource planning

- Real-Time tracking and progress reporting

- Less shorts or overages on project

- 100% Traceability of Materials and Qualifications

- Best marking and identification in industry

- ISO specific packaging / tagging for field supports

- Field-Assist Drawings (FAD) for SAFER, FASTER installation

- DELTA TRAX eliminates time spent searching for supports

- Secure Customer Portal allows real-time insight for expediting

Have a project? Ready to try a better way?

Contact DeltaFrom ISO take-off ...

through manufacturing ...

through manufacturing ...

to custom tagging and packaging by ISO ...

to SAFER installation...

to SAFER installation...

The Difference Extends to Field Installation

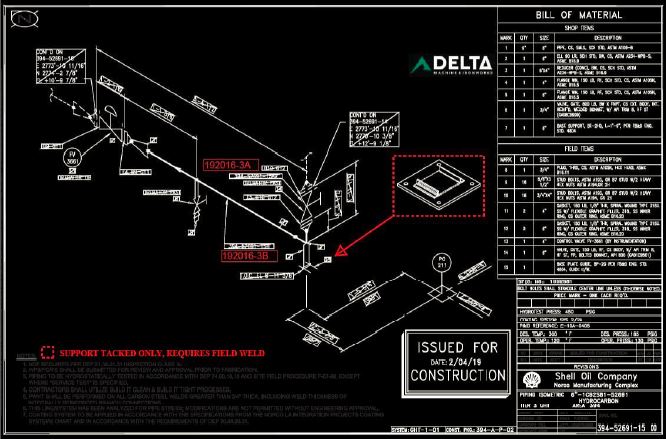

Delta’s Field Assist Drawings, FADs as we call them, help craftsmen and the material control team locate the right supports in the lay-down area. Our FADs also show the craftsman where the supports are designated for on each isometric. And to take it one step further, in keeping with Delta’s commitment to safety, both in our shop and your job-site, we identify all “tack-only” supports to ensure that they are handled with extra caution and that field welds are completed after adjustments are made.

DELTA TRAX

In partnering with our customers to better understand the challenges with supports, we have learned that keeping-up with all of the supports on the job site, is challenging all by itself! Delta is pleased to offer Delta TRAX as our newest addition to our TSS suite of services! We have partnered with Samsara to offer GPS tracking for any Delta shipment.

Each collapsible shipping container is equipped with a GPS tracker. Tracking information is updated each time the container is moved and every 12 hours. Delta can provide location history upon request or at a scheduled frequency. Additionally, we can assist with setting up your own personal or company portal into our Samsara tracking portal to monitor movement of Delta containers. When all material has been removed from the containers and they are no longer needed, you simply return to Delta or contact us to arrange pick-up.

Tracking by container means that you can know the exact GPS coordinates any time you need to locate a specific support! With 40-60 supports per container, this solution is affordable and virtually eliminates time searching the lay-down yard for Delta supplied supports.